Innovations

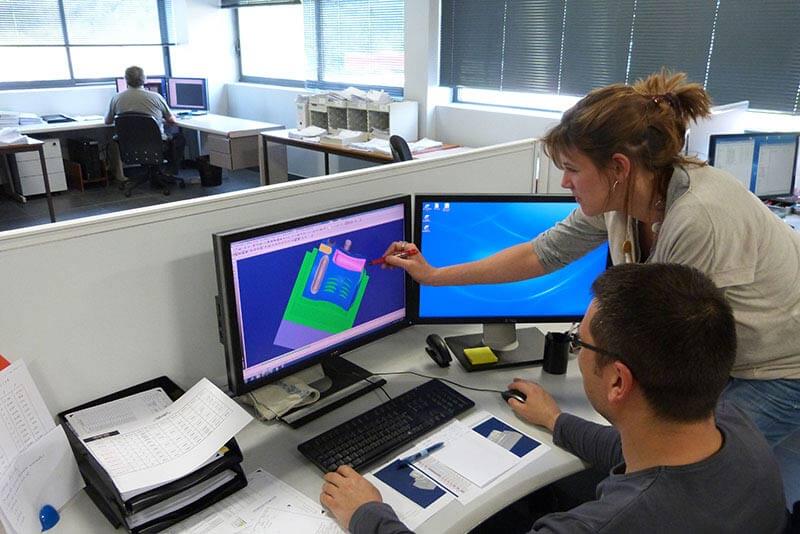

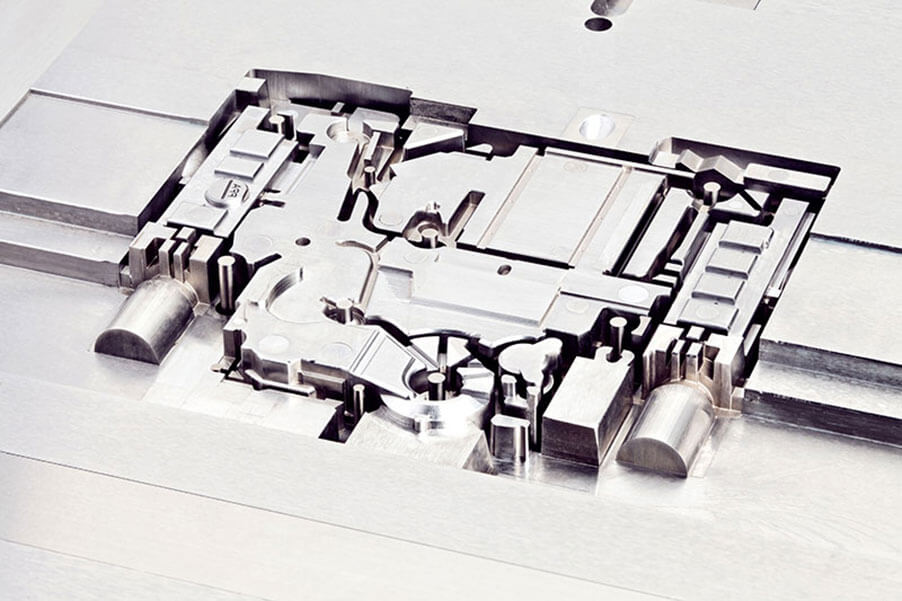

Thanks to a constant innovation and important investments in R&D of plastics processing, SMP is one of the leaders in high-technology mould domain.

Innovate to combine performance and efficiency

Innovation and market anticipation are a daily concern at SMP.

We invest about 8% of our turnover in the R&D.

Thanks to ultra-modern tooling, offering the best results, we are able to develop technologies combining performance and efficiency.

MEDIUM TERM STRATEGIC PROGRAMS

Contact us

Find out more about our services and know-how ?

Do not hesitate to contact us.